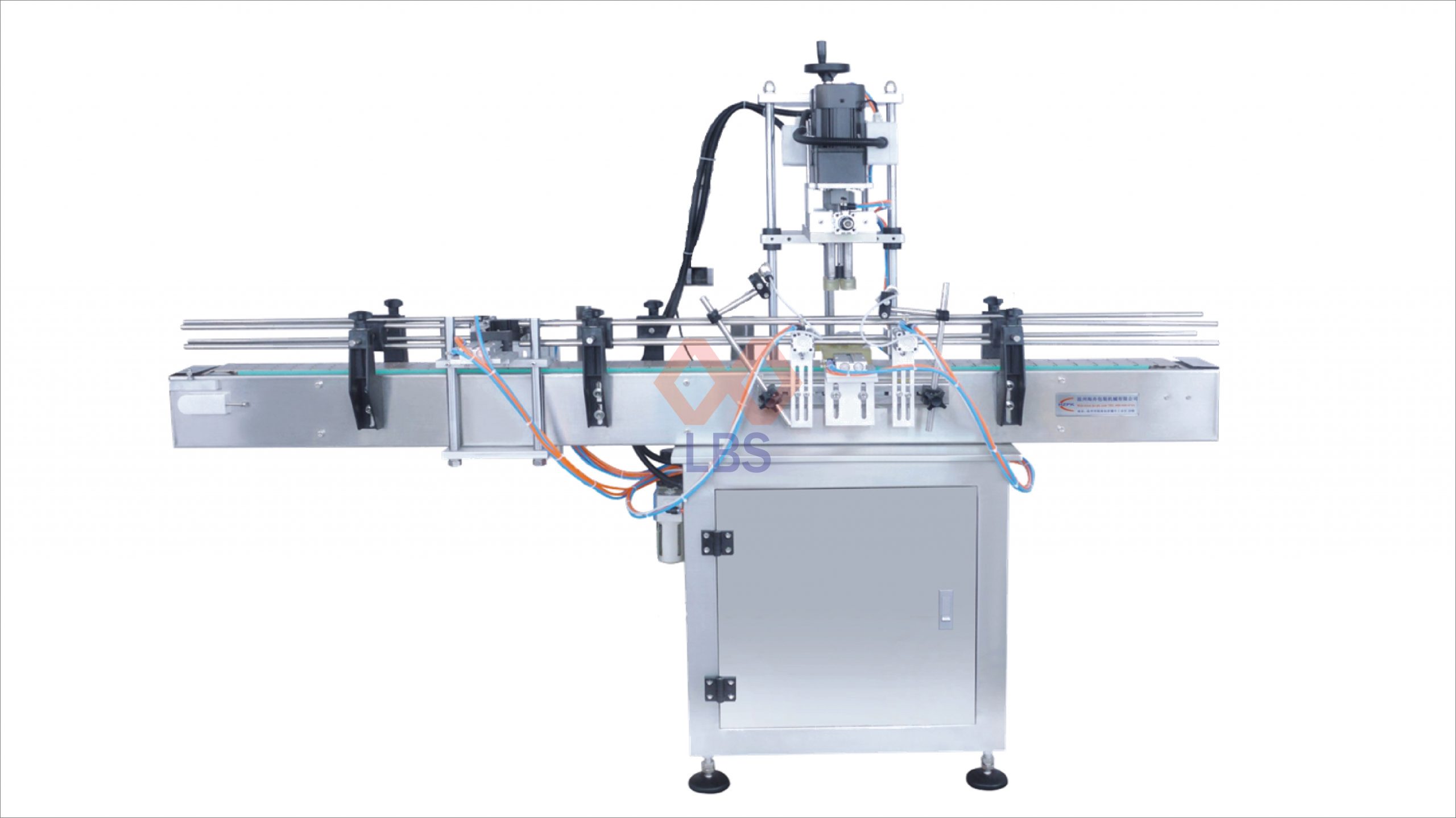

Automatic Capping machine (with servo motor)

Basic configuration and parameters

Overall size: 2000mm * 800mm * 1550mm (including the size of conveying line)

Overall weight: 175KG

Equipment material: SUS#304 stainless steel and aluminum alloy components

Working height of conveyor belt: 820-880mm

Plane width of conveyor belt: 114mm

Working voltage: 220V 50Hz / 60Hz

Working pressure: 4-6Mpa

Control mode: PLC programmable controller / Brand: (servo type) Huichuan brand

Operation mode: the man-machine interface (touch screen 7 inches) (servo type)

Capping motor: 60W / 50Hz; (servo type) Huichuan brand servo motor is used

Pneumatic components: air cylinder–Xingchen brand, solenoid valve–Xingchen brand

Workpiece identification: optical fiber / reflective type, Fuwei brand

Suitable workpiece size: diameter 30-120mm

Suitable workpiece height: 80-350mm

Cap locking range: 20-70mm cap

Capping (type): duckbill pump, spray pump and other pump heads, nozzles, ordinary round screw cap (referred to as multi-functional capping machine for short)

One set of tensioning device: stepping motor drives the belt mechanism, as the function of bottle clamping, motor brand: Leadshine

Attribute: lock caps with torque (adjustable torque)

Total power: 1KW

Air source used: 4-6kg / cm

Conveying mode of conveyor belt : intermittent or continuous, switchable